Agile Methodology: User Stories

In the past few weeks we’ve been discussing Agile methodology to iteratively develop custom software that better meets the need of our customers. Probably more important than this concept, however, is to to define the business need before we ever begin a project. The way we accomplish this is by creating user stories.

RFID Technology and Oil & Gas: Streamline with Custom Software

Oil and Gas RFID Software

We are all pretty familiar with RFID technology, as most big ticket items we see at the store are protected by them. When it comes to the oil and gas industry, the uptake has been much lower, which is surprising when you think about how much more they stand to lose. If a pipe goes missing, or even worse, doesn’t get needed repairs because nobody could find it, the stakes are upwards of thousands and millions of dollars.

Spotfire Dashboard Demo of a Shale Type Ternary Diagram, Well Map, and Source Wells by Formation

Since rock type will have a bearing on completion and drilling practices, you definitely want to know the results of wells with similar rock types. Normally, geologists, petrophysicists, and reservoir engineers who need to find data from wells and formations by rock type to perform evaluations have to plot out data in Excel, but making selections off of an Excel chart is impossible, and filtering table data can often end up being hit-or-miss. Instead, you could create a ternary diagram in TIBCO Spotfire paired with a geographic map of the location of the wells to perform formation evaluations. The Spotfire dashboard demo here provides interactive functionality with a well map and ternary diagram.

Click the video to play the demo:

As you can see, there will be a direct bearing on what to pay for land in a shale oil or shale gas play when you monitor how the lithology of a formation is changing by moving your area of interest.

To purchase a version of this Spotfire dashboard tailored to your own data, give us a call at 1-888-343-KNOW or send me a note using the form to the right.

How custom software ages | Application Development Video Series, Episode 1

We don’t typically think of software as something that can age. The code is written and run on a computer, so it doesn’t age like hardware does or like people do. It becomes obsolete or becomes less functional, unable to keep up with the demands of the business and the business users. Software is usually written based on a snapshot of a business need for a certain period or range of time. Unfortunately, software doesn’t change dynamically the way the business does. Businesses can change, market demands can change, the number of users can change, and the software can have trouble keeping up with that.Read More

Data Management for Oil & Gas: High Performance Computing

Data Management and Technology

The oil and gas industry is dealing with data management on a scale never seen before. One approach to quickly get at relevant data is with High Performance Computing (HPC).

HPC is dedicated to the analysis and display of very large amounts of data that needs to be processed rapidly for best use.

One application is the analysis of technical plays with complex folding. In order to understand the subsurface, three dimensional high definition images are required.

The effective use of HPC in unconventional oil and gas extraction is helping drive the frenetic pace of investment, growth and development that will provide international fuel reserves for the next 50 years. Oil and gas software supported by data intelligence drives productive unconventional operations. Read More

Data Management & Technology: Secret to Oil & Gas Growth

Data Management the Key for Unconventional Success

Data management and new technology is lowering the risk level for unconventional oil and gas E&P. This has become apparent in recent years and is a radical change from former risk levels of investment.

Computational analysis is at the heart of risk reduction and the ease with which entrepreneurs in this field are now finding funds. is more important than ever before. Read More

Bad Oil and Gas Software: Key Concerns

Oil and gas software is an essential component for businesses in the energy industry. It allows them respond to problems more quickly, review historical data more easily and send reports to managers automatically.

Oil and gas software also allows enables the implementation of a formal process for tracking production as opposed to the collection of spreadsheets that has traditionally been used in this industry.

However, poor oil and gas software can also create problems, which may be classified into the areas of assets, production and revenue. Read More

Oil and Gas Software: IT is Adapting in a Brave New World

Oil and gas software helps support IT transformation into valued business partner

It’s no secret that the exploration, drilling and production industry is not the same industry it once was, and oil and gas software can provide companies with the new  capabilities they need to respond to the increasingly competitive environment around them. In a recent article from The American Oil & Gas Reporter, titled “IT Leaders Embrace Challenging Transformation In Upstream Operations”, Johnathan Zanger and Gerry Swift discuss how change in the oil and gas industry has created both challenge and opportunity for IT.

capabilities they need to respond to the increasingly competitive environment around them. In a recent article from The American Oil & Gas Reporter, titled “IT Leaders Embrace Challenging Transformation In Upstream Operations”, Johnathan Zanger and Gerry Swift discuss how change in the oil and gas industry has created both challenge and opportunity for IT.

Zanger and Swift argue that oil and gas companies have a choice: they can either look at IT as a necessary but inconvenient utility—that is, they could continue to look at IT the same way they always have—or, they can start looking at IT as a valued partner that can help meet desired business outcomes.

Decision Making and IT

Zanger and Swift analyzed data provided by seven different exploration, drilling and production IT groups to gain a better understanding of how decisions are being made in these organizations, and how these decisions affect the business. The results of the analysis show a number of ways that growing the partnership between IT and line of business can benefit oil and gas companies:

- Improved data management

- Greater customer satisfaction

- More opportunities to innovate

- More well-defined corporate structure

Improved data management

As oil and gas companies change the way they operate, they must also change the way they capture, analyze and apply data. It’s no longer sufficient to gather data just for the sake of gathering data. Successful companies must be able to capture pertinent data that can be directly applied to business operations. Oil and gas software can provide the data management capabilities needed to make this happen.

Greater customer satisfaction

Ensuring customer satisfaction has long been one of the most important objectives of oil and gas IT organizations. However, changes in the oil and gas industry have also altered the meaning of the term “customer satisfaction.” It’s no longer just a matter of meeting business objectives and focusing on customer needs. IT organizations now need to make themselves truly customer-centric, aligning themselves to provide business value, before the customer even has to ask.

More opportunities to innovate

The importance of innovation in the oil and gas industry is well established. What seems to be less clear is the difference between change and innovation. Innovation constitutes a change for the better, that opens a new and more effective way of doing things. Many oil and gas companies have difficulty identifying innovation opportunities, but Zanger and Swift predict that a greater partnership between business and IT would make these opportunities easier to find.

More well-defined corporate structure

In order for IT to support the business effectively, there must be established processes in place to show the alignments and accountabilities of everyone involved with the IT organization. IT organizations can no longer continue to exist in their own little world. In order for IT organization to provide true business value, they must understand their relationship with the business, and be able to collaborate consistently.

One of the key misconceptions that Zanger and Swift try to do away with in their article is that changing IT requires bleeding-edge technological solutions. In reality, the solutions needed to drive greater IT involvement with business processes already exist, and they’re already proven. IT just needs to find new ways to apply these tools, such as oil and gas software, to support their mission.

For more on this topic, read this article on how the IT service model is changing…

SharePoint Consulting: Gamification and ROI

The Return on Investment for SharePoint Consulting

In our SharePoint consulting engagements, we often come across interesting problems that can be solved by some amount of customization. This was exactly the case when a change manager from one Upstream client came to Entrance with concerns over educating employees on a new system transition.

Pipeline controllers at this company needed to understand the changes and how they affected their jobs. After some consideration of the business problem, Entrance recommended that our client try SharePoint gamification.

We shared some of the steps we went through for this SharePoint consulting engagement when we first started the project a few months ago. Now that the gamification customizations are live on the customer’s SharePoint site, it has been exciting to see how they are using it and what employees think.

Incentivizing SharePoint Participation

A common problem in the SharePoint consulting world is when sites are developed and implemented, but afterwards stakeholders have no idea who is using it or if it is serving the purpose for which it was developed. As a result, calculating ROI or any sort of value for the project is not possible.

A common problem in the SharePoint consulting world is when sites are developed and implemented, but afterwards stakeholders have no idea who is using it or if it is serving the purpose for which it was developed. As a result, calculating ROI or any sort of value for the project is not possible.

In the case of this implementation, the site was launched with incentives (like gift cards and t-shirts) for people to participate and build up points. The addition of fun and competition immediately encouraged employees to use the site and become engaged.

Similar to a computer game, each user starts out at a basic level and moves up as they score points. Each level is named after something relevant to the oil and gas industry.

There is also a leaderboard where employees can see monthly and lifetime high scores. This helps the change management team to check in on who has been staying up-to-date on system migration changes, and who has not.

Another major benefit of our SharePoint consulting work is that the gaming system has been set up so it can be managed internally. After the customization was complete, Entrance trained the team on how to administer it, thus empowering the team to use the system as necessary.

Since the launch of gaming system, reports back from the client are all positive. Employees report that they love playing, and the client is thrilled that so many people are engaging with the content they need.

For more on how the oil and gas industry can use SharePoint to improve collaboration and engagement, check out this post…

Custom Software: Game Changers for Oil & Gas Service

Custom Software for Service Companies

In the oil and gas industry, every company has a different need for custom software. Every business faces unique issues that can only be addressed by custom software.

Custom software applications can provide oil and gas companies with a variety of benefits, including:

- More effective inventory tracking

- Automation of repetitive and error-prone tasks

- Easier access to information

More effective inventory tracking

It’s no secret that equipment used in the oil and gas industry is expensive. Knowing how much is spent on equipment and how effectively equipment is being utilized can be a key factor in determining profitability.

One major equipment rental company was able to use a custom inventory tracking application to make sure that they weren’t paying for more equipment than their customers could use.

In addition, the company used the application to provide inventory tracking services to their customers, so that the customers could plan ahead to make sure they were renting the right amount of equipment. The customer-facing portion of the application became a key differentiator for the company by providing value to its customers.

Automation of repetitive and error-prone tasks

Any software solution that requires just as much work to complete a task as it would to do the task manually is an example of bad software. Effective custom software solutions can automate repetitive tasks like copying and pasting or exporting data, decreasing the amount of work that employees must perform.

Automating repetitive tasks makes employees more productive, and decreases the likelihood of human error.

Easier access to information

In the oil and gas industry, having access to the right information at the right time is key. One company that specializes in pipeline logistics needed a solution that could provide needed information in the event of a pipeline accident.

If this were to occur, the company’s customers would need access to information on the history of individual pipes, and finding this information was very time consuming for the company. They used custom software to provide easy access to this information, helping them become more efficient and provide a better experience for their customers.

No matter what challenges a service company is facing, a custom software solution can probably be developed to overcome them.

For help assessing how to evaluate what software solution would fit your business’s needs, check out our series on software selection.

Oil and Gas Software: Decision Making and Forecasting

Oil and Gas Software and the Accuracy of Decisions

Oil and gas software can be one key to integrated, well structured, well defined IT systems. Data support utilizing an oil and gas specific framework leads to intelligent decision making and a reduction in overhead.

Case study: Oil and Gas Business Intelligence Framework

Data access, forecasting and analysis, reporting and decision making software for dedicated professionals, from the field to the boardroom, are available with solutions developed by Halliburton, Dell, Qualcomm and Microsoft.

The Oil & Gas Business Intelligence framework, iLink, offers a comprehensive real-time overview of your business. You can track performance metrics that will provide you with the necessary information to make informed business decisions. Dashboards offer an easy to access overview. The process of resource optimization will help to make reliable forecasts based on the most current data. Managers and technicians in the field can communicate data, while tickets and alerts can be created for field personnel.

The Oil & Gas Business Intelligence framework, iLink, offers a comprehensive real-time overview of your business. You can track performance metrics that will provide you with the necessary information to make informed business decisions. Dashboards offer an easy to access overview. The process of resource optimization will help to make reliable forecasts based on the most current data. Managers and technicians in the field can communicate data, while tickets and alerts can be created for field personnel.

iLinks key features are:

· Identifying Key Performance Metrics

· Monitoring Well Performance

· Creating and assigning well issue ticketing and alerts

· Global well map

Microsoft’s partnering with Halliburton has developed the architecture for their oil and gas upstream framework, MURA. This architecture supports business with the goals of gaining maximum insight from business data and maximizing worker productivity. The framework supports real time analytics, including robust statistical and analysis packages for data mining, research and consumer reporting.

It also supports stream-processing engines capable of detecting and filtering real-time events, on site or in the cloud.

Information integration enables diverse data and software to seamlessly function without being trapped in a pipeline to nowhere. Workers need tools that help them gain deeper insights into ever growing quantities of relevant data.

Simplifying the process of finding, selecting, and exploring their data in flexible ways is essential. This process needs to be intuitive for them, and they should not have to rely on IT to fetch data or write custom reports.

You can deliver cost effective solutions with MURA that are highly mobile because of interoperability in the cloud and on-site. MURA supports industry standards. An industry wide interface makes new, competent implementation such as PPDM understandable and manageable.

MURA interfaces are published for open industry use. All the elements of an interface are well defined so that applications can be independently developed once per function. Wasteful duplication of effort can be avoided.

Information models employ a consistent naming system for referring to assets. This makes information sharing, exchange and comprehension an understandable process.

Security implementation is robust and well defined, including authentication, identity lifecycle management, authorization, certificates, claims and threat models. This facilitates secure interoperable design and deployment. Solutions that integrate business processes, workers, workflow and IT processes with essential and immediate data support intelligent workflow.

Business Intelligence in Action

K2 uses MURA to manage declining well process. The MURA framework provides guidance for oil and gas companies for creating a dashboard of applications that are integrated at the user interface layer.

This kind of oversight capability gives well operators the data and context they require be alerted to issues that need timely corrective action. K2 optimizes information provided to decision makers, while minimizing data that is superfluous or in an obscure format. IT departments appreciate MURA and K2 because costs are restrained while business demands are effectively met.

Demand forecasting simplifies and automates enterprise-wide forecasting, and improves the quality and measurability of marketing planning. When you improve accuracy significantly, it is likely to result in improved capital decisions and effective communication that will ultimately bring a reduction in overhead and operating costs.

For more on how oil and gas software can help your business, read this post on the benefits of analytics.

Four Reasons to Consider Software Consulting

Software Consulting and the Right Team

During our ongoing discussion on quality and custom software, Entrance’s software consulting team recently covered what we bring to the table for our clients.

As a buyer, you may have wondered why you should hire an outside programmer versus building an internal team. What follows is a four great reasons why the investment in software consulting is worth it for your company.

Exposure to Many Industries and Practices

As software consultants, we get exposed to many different companies and industries, so part of the value we bring to the table is our diversity of experience. Our clients may be asking for a specific request, in a specific way, because they are unaware of any other way to do things.

We can help them diversify their options by sharing our knowledge and experience from other clients and projects, especially when those clients and projects are in a different industry. Other industries may have been doing something for a long time, and consider it standard practice, but that same process could be a revolutionary innovation in a completely different industry.

As an example, think about FedEx, who applied a hub-and-spoke concept that revolutionized the overnight delivery industry.

Subject Matter Expertise

Yet another way we add value is by becoming a subject matter expert, either for an industry as a whole, for specific operations within an industry, or for a series of technologies. One specific place where Entrance shines in this regard is our deep expertise in oil and gas software and integration solutions.

Then we become advisors, coaches and mentors to our clients, thereby reducing their efforts to make decisions that are right for their company and industry.

Saving Time for the Tasks that Matter

One of the best value-adds our clients have seen from software consulting is that we can improve processes so that they can focus their energy on doing what they do to add value. Usually this is improving workflows or automating data gathering and reporting.

Over and over again, clients tells us, “This isn’t my job, this is just the stuff I have to get out of the way to GET TO my job.” A trusted team of software consultants can help your employees get past those road blocks that waste their time on a daily basis.

Beyond freeing up time that may have been spent on time-consuming tasks that don’t bring value, software consulting can also address problems that have been languishing at your business for a long time.

A lot of times, customers see a need for improvement, but do not have the capability to implement that improvement while also maintaining existing commitments. Frequently, we are in a position to take care of this without interrupting the normal flow of business.

Fresh Set of Eyes

When your company is dealing with a long-standing problem, a fresh outlook may be just what you need to get it solved. Far too often, people cannot get to the root of their own problems, which prevents them from coming up with insight that leads to worthwhile solutions.

Some people may not have a mindset of curiosity, others are uncomfortable with change, and many are too busy to dig deep and solve problems. As a result, companies tend to lean on tired solutions that only half work.

When an Entrance software consultant starts a new engagement, we focus on identifying how our clients deliver value to their customers, and then find the roadblocks that stand in the way of that happening. We use questions and our outsider perspective to break each piece down to its essential components and build it back up again in a way that is novel and valuable.

Turning Your Business Goals into Reality

As your company considers internal versus external resources for software, qualities like domain knowledge, inter-organizational experience, technical knowledge, and providing additional capacity to deliver solutions to match business initiatives should all be considered.

For more on how software consulting can help your company make decisions that are right for the business, check out our series, “Software Selection: Buy versus Build.”

SharePoint Dashboards: Three Reasons to Build Your One-Stop Shop

Surfacing Vital Information with SharePoint Dashboards

Your Sharepoint dashboard is similar to the dashboard in your car; it contains all the information that is pertinent to your oil and gas operation so you can easily and quickly find what you need. If you haven’t set up your dashboard, it is important to contact a Sharepoint consulting firm to help you get started on this vital task.

The benefits of having your Sharepoint dashboard fully operational are numerous. Here are the basics of the Sharepoint dashboard to help you get an understanding of why it is so important for your oil and gas business.

One-Stop Shop

Like I said above, the dashboard is your first stop for information, and should contain relevant items that are used by employees for daily functions. You can include so many things on your dashboard, from forms to stock quotes, maps and plans, and even statistics and budget information.

Like I said above, the dashboard is your first stop for information, and should contain relevant items that are used by employees for daily functions. You can include so many things on your dashboard, from forms to stock quotes, maps and plans, and even statistics and budget information.

The dashboard is completely customizable to the needs of your business and to support your daily operations. Your Sharepoint consulting professional can help you determine how you’d like your dashboard to be set up, and what information you need to include.

Drill-Down Menus

The drill-down menu options on the Sharepoint dashboard are one of the most popular among users. You can have many types of drill-downs on your dashboards, with links to information on companies, rigs, wells and assets. Here are a few examples to get your creative juices flowing:

Company –> Field –> Well

Company –> Asset –> Field –> Well

Asset Type –> Field –> Well –> Completion

Area –> Block –> Lease –> Well –> Completion

Plat –> County –> Lease –> Well

As you can see, the options for drill-down menus are endless, and can link to numerous pieces of vital information on current and closed operations.

Filters

Filters are also important when you are setting up your Sharepoint dashboard. You can add filters for operational and non-operational wells. You can also filter by product type, such as oil or gas wells.

Geographical data can be another way to filter information. This allows the user to quickly and easily find the information they need, so they aren’t spending all of their time trying to find what they need to accomplish their mission.

Visualization

Your Sharepoint dashboard also helps users to visualize information so they can gain a better understanding of trends and performance indicators. This will also assist in making business decisions and help further your business reach. You can add charts and graphs to make the information easier to understand and retain.

The Sharepoint dashboard is one of the most important aspects of your Sharepoint site, so it’s important to do it right. Once you have your dashboard set up, it is fairly easy to maintain, and this duty can be handled by an employee in just a few minutes a day.

You will also find that operations run more smoothly when everyone has instant access to the information that they need!

To see how SharePoint dashboards helped one Entrance client accomplish this, check out this case study.

Software Selection: Assessing Business Drivers

Software Selection and Your Business

Making good choices during the software selection process is critical to your business. Whether you go with an off-the-shelf product, a custom application, or something in between, the investment in time and resources means that your company will be using that software for years to come.

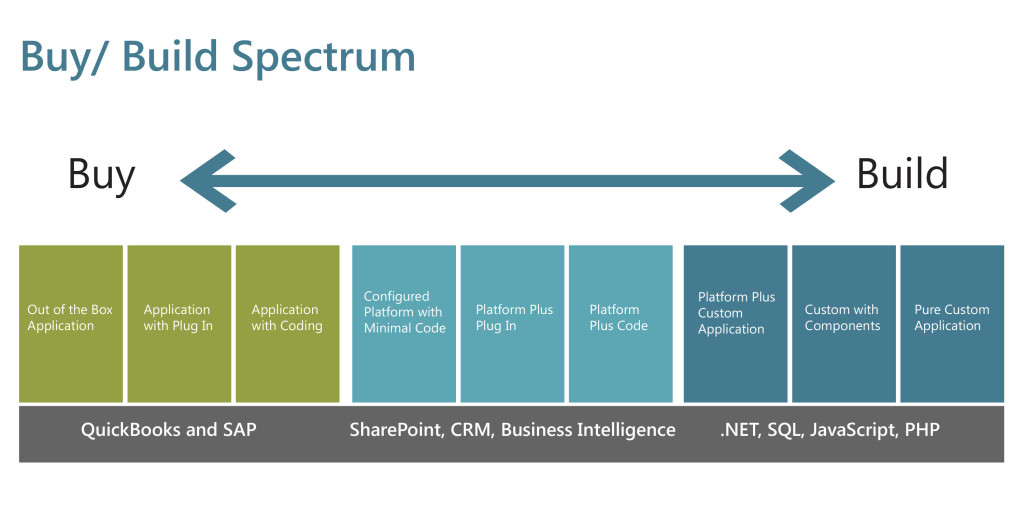

We started a series on the topic of software selection that will lead you through some of the key concerns around this process. Check out part one on the buy versus build spectrum here. For illustrative purposes, check out the below infographic, which can help your team understand the range of available options when it comes to software selection.

Keeping Up With Evolving Software Capabilities

Periodic reassessment of the IT solutions serving your core business needs should also be an integral part of your systems lifecycle management. We all tend to focus on our daily operations and making best use of the tools at hand, but it’s prudent to regularly research available software applications that may enable your company to work more efficiently and at less cost.

Are you using an off-the-shelf application for your major operational needs, but employing custom designed software for specialized applications? IT providers are constantly upgrading and expanding the range and depth of their software and software services. Revisiting your current applications in light of newly evolved products and services may lead you to more efficient and less expensive software solutions.

Evaluating Off the Shelf Options

When analyzing how to best meet your IT needs, out-of-the box products should be examined first, as they’re usually less expensive than customized solutions offering the same functionality, and require less deployment time. Is there a proven off-the-shelf application that fulfills your operational requirements, or can do so with optional available plugins or slight coding changes? If so, you should strongly consider it.

Classic examples of this are Oracle’s or SAP’s back office applications. In the arena of E&P operations, where production data must be quickly gathered, transmitted and assessed, Merrick System’s eVIN software is a premier off-the-shelf solution, easily integrated with upstream business and decision-making systems.

Less easily determined is how best to support key functions such as business intelligence, which derive their data from existing databases, but are supported by specialized applications structured to meet their firm’s unique needs. Some of the business intelligence applications critical to the Upstream industry, such as operational, supply chain and asset management, often employ sophisticated, integrated data management solutions available from experienced E&P software consulting firms.

Evaluating Custom Software Options

There will always be some key business functions requiring innovative customized solutions. Written in such languages as JavaScript, SQL or PHP, these applications derive their data from core databases or data warehouses, but are often built to meet the specialized requirements of senior management.

On line analytical tools (OLAP) are an example of such customized applications. Created by software consultants to help interactively analyze multidimensional data, OLAPs rely upon information drawn from a company’s data warehouse.

Although the processes and rules that drive your business may be inherently stable, the software applications that help you manage and plan are constantly evolving. IT firms and consultants are fast developing new products to reap the burgeoning potential they see in the booming E&P industry. Periodically reassessing their offerings in light of your business needs, budget and current applications takes some time, but can return large dividends.

For help with the software selection process, sign up for a software audit today! We can help you understand how well your current software integrates, and then make recommendations on how to choose new software that fits with your existing and evolving business needs.

Oil and Gas Software: Real-Time Information Improves Collaboration

SCADA and Oil and Gas Software

Providing upstream SCADA information systems with near real time field metrics using oil and gas software is essential to the efficient management of shale gas exploration and development. Rapid, informed response to fast changing dynamics across multiple upstream sites requires reliable source data capture and quick availability.

Mergers and Acquisitions Outlook for Oil & Gas: Integration a Key Hold-up

Mergers and Acquisitions for 2014

The Rice Energy Finance Summit promotes forward-looking discussion on important energy issues, like mergers and acquisitions, and facilitates relationships in this business sector through the exchange of information and ideas.

Data Management: Information Security for Oil and Gas

Threats to Data Management and Information Security

According to a recent report by Booz Allen Hamilton, one of the big data management concerns for the oil and gas industry is information security. According to the report, oil and gas companies are at a constant threat of being hacked, and there is only so much these companies can do to prepare themselves for this threat.

Data Management: Leveraging Unconventional Assets for Oil and Gas

Unconventional Assets and Data Management

New risks create a need for improved data management in the oil and gas world. One of the greatest risks in unconventional shale development is the risk of not being able to manage an increasingly complex group of assets in an environment that is constantly changing.

Data Management for Oil and Gas: Unconventional Data versus Big Data

Unconventional Data Management

In Unconventional Hydrocarbons, Big Data, and Analytics, Allen Gilmer of Drilling Info (DI,) explores unconventional data management in the hydrocarbon industry. Each day about 50 experiments take place.

SharePoint for Upstream: Branding

How can SharePoint branding help my company?

Sharepoint branding is important for all businesses in the oil and gas sector, because matching the site to your company’s look, feel, and workflow can improve utilization. Most SharePoint sites contain a lot of important information that goes to waste if that site is not user friendly.