Oil and Gas Data Management: Getting Ahead in a Challenging Atmosphere

Oil and Gas Data Management Options

Data management involves handling data throughout its life cycle in addition to the infrastructure upon which it resides. The amount of data that oil and gas companies generate is continually growing, as is the infrastructure upon which that data resides.

Oil and Gas Software: Top Concerns from Merrick Users

Getting the Most from Oil and Gas Software

A few weeks ago, several Entrance software consultants attended an event on oil and gas software, the Merrick MUG user conference. We’ve already covered this event in a blog post on knowing when to upgrade energy software.

SharePoint Consulting for Oil & Gas Service: Dashboards

Transforming Workflows with SharePoint Consulting

For many oil and gas service companies, the many moving pieces of daily operations can be smoothed with SharePoint consulting. One such Entrance client took advantage of this with a dashboard that tracks work throughout the entire lifecycle.

Oil & Gas Software: When it’s Time for an Upgrade

Oil & Gas Software with Merrick

There comes a time in the life of any oil and gas software product when it’s time to consider modernization. Several Entrance employees attended Merrick’s user event, MUG, earlier this week.

The Data Management Business Case

Transforming the Numbers With Data Management

Increasingly complicated data sets, like the influx of production data for oil and gas, can require more robust data management strategies than we’re accustomed to. Excel or other small ad-hoc databases just aren’t up to the job of complex data warehousing. In addition, these more primitive solutions don’t provide the visibility or dashboards that are required by most decision makers.

Data Management Problem Solving: Data Entry

Data management in the Field

Capturing information in the field can be a difficult data management problem due to lack of connectivity. The sheer volume of data and paper based processes can also be concerns.

Lease Compliance and Custom Software: Eliminating the Single Point of Failure

Onshore Drilling and Lease Compliance

Does your company participate in onshore drilling? If so, you would probably agree that lease compliance is an ongoing issue. Onshore wells are smaller, so you have more of them, with the accompanying lease provisions that your company may or may not have a system for tracking.

Oil and Gas Software: Start with Problems, Not Solutions

We Need Oil & Gas Software Solutions – Or Do We?

The Harvard Business Review published an article by Bart Barthelemy and Candace Dalmagne-Rouge called, “When You’re Innovating, Resist Looking for Solutions,” that every decision maker should read before committing to an oil and gas software solution.

Software Selection: the Buy versus Build Spectrum

Software Selection Matters for Your Business

In our evolving world, good software can be one of the most effective differentiators that a company can leverage for growth. Implemented thoughtfully, software can be a multiplier for your existing staff, or it can surface information for better decision making that was previously locked away in spreadsheets.

SharePoint Consulting for Oil and Gas: Integrating GIS Maps

SharePoint Consulting Streamlines GIS Mapping

In our SharePoint consulting work, we see opportunities every day for oil and gas companies to streamline their operations and make information easier to find. For upstream companies, the insight that can be gained from geographic information systems (GIS) is well worth the effort of implementation.

Oil and Gas Software: Moving the Needle on Decision Making

Oil and Gas Software and Lack of Integration

The Harvard Business Review posted a blog this week called, “Four Areas Where Senior Leaders Should Focus Their Attention,” that applies to how leaders in the energy industry should look at oil and gas software.

Custom Software Application Provides South American Producer with Improved Inventory Tracking

Preventing Inventory Loss with Custom Software

Entrance has long partnered with Midstream service company TG Mercer to develop a custom software application, called SpreadBoss, that provides cradle to grave pipeline tracking. This past year, TG Mercer started working with one client in South America to provide better tracking of their inventory.

As they looked further into the project, TG Mercer realized that adding modules on to SpreadBoss would be the best way to provide the visibility this producer needed.

The first of these additions is the ability to divide large yards into zones, with a catalog of corresponding inventory in each zone. In addition, as employees check inventory into a given zone, they have the option to define a new item in the database, which was previously not possible.

See the picture to the right for an example of zoning in the application.

Quality Control Capabilities

An inventory reconciliation module takes this process a step further. On a quarterly basis, the customer can validate the complete inventory in a given zone. Employees scan every item, and when this is complete, SpreadBoss compares the expected inventory with actual inventory. Items that are lost or in the wrong zone can then be logged for action.

This quality control process will help TG Mercer’s clients to achieve better control of high value inventory. Particularly as the size of oil and gas facilities increase, this level of visibility will help prevent assets from hiding in plain sight.

For more on the benefits of custom web applications, check out this page. Read more about our partnership with TG Mercer here!

Data Management and the IT Service Model for Oil & Gas

Data Management and the Digital Oilfield

As we’ve covered in a previous post, when it comes to data management, more data isn’t always better. But more complete, real-time data can be a key differentiator if it is tied to notifications and actionable business intelligence.

I ran across an article in Venture Beat from last year discussing five trends in oil and gas technology. The first trend discussed a McKinsey report that described the digital oil field: ““instruments constantly read data on wellhead conditions, pipelines, and mechanical systems.

That information is analyzed by clusters of computers, which feed their results to real-time operations centers that adjust oil flows to optimize production and minimize downtimes.”

Proving Out Investments in IT

The article went on to say that while “total upstream energy IT support spending is about 25 cents per barrel of oil,” some analysts “believe digital oilfield technologies could increase the net present value of oil and gas assets by 25%.”

Even as the energy industry makes these investments in higher quality data from the field, returns of 25% or more are very dependent on management of data once it reaches the front office.

The Harvard Business Journal recently published a blog along these lines called, ‘Don’t Just Serve – Enable: A new Model for IT Organizations.’ As the author, Bill Franks highlighted, “Business users need increasingly fast, broad, and flexible access to data.”

Changing the IT Data Service Model

One hold-up to this access can be the IT process, which because it has to serve everyone’s needs can often seem to fill no one’s. Particularly for oil and gas, “IT must shift focus to enabling access to the range of raw data elements that go into” traditional views and reports so that users can “mix and match data as required for their specific problems.”

As Upstream companies work to get the most value from their investment in each and every well, better data management may be the key to increasing production without a matching investment in new wells.

Since traditional reports often don’t enable users to dig as deeply as they need to, Franks suggests creating discovery environments.

“Within a discovery environment, users can query a broad range of data, create output data (which is not typically allowed in such systems), and even load new data.”

Discovery Moves the Needle on Data Management

These discovery environments, says Franks, have been a big success factor for many large companies. The big reason for this is that it’s easier to experiment “since they are already working within the scalable systems that will be used to deploy their findings, it is much easier and faster to move from prototype to final product.”

For an E&P company, this could mean iterating and making improvements to the process of drilling after only five wells instead of ten. Over time, these efficiencies could make a huge difference in production.

It can be difficult to challenge long-standing methods of looking at data. Oil and gas companies can’t afford to do anything less if they are to keep up in such a competitive industry. As Franks remarks, “Why wouldn’t you want people empowered to freely search for the next great business-changing analysis?”

For more strategies on making data a benefit, not a burden, for oil and gas, check out this post…

Energy Software Reporting: Surfacing Production Data with SharePoint

Energy Software Reporting

Production reports, even with the help of sophisticated energy software, are nothing new for the oil and gas industry. Enabling access to these reports and keeping them up to date can be an issue, however.

Data Management for Oil and Gas: More is (Almost Never) Better

Management of proliferating data

90% of the world’s data has been generated over the last two years. As a result, data management has become increasingly complicated. Nowhere is this truer than in the upstream industry, where the pace of Shale drilling has more than doubled in recent years.

Energy Software and Production: Three Reasons to Commit Today

Energy Software and Optimizing Production

Amidst reports that Texas production has grown to account for 34.5% of total US figures, energy software is becoming more important for drilling optimization than ever.

Custom Software: Tracking Pipeline Damage for Oil and Gas

Releases (or leaks) are very important to pipeline companies. Common causes for these leaks are equipment damage, both internal and external corrosion, manufacturing failures, and natural hazards like shifting land. The U.S. Department of Transportation’s Pipeline and Hazardous Materials Safety Administration (PHMSA) is responsible for releasing reports regarding pipeline releases or leaks. As a result, the ability to track damage that could cause pipe failure and report on it is important.

Energy Software: Leading Indicators, Lagging Indicators, and Safety Compliance

When it comes to safety for oil and gas, it’s easy to get overwhelmed by the intricacies. A culture of safety needs to filter throughout your organization, and this involves having a plan for how to accomplish this.

Custom Energy Software: Following Pipelines from Cradle to Grave

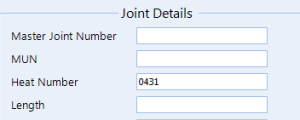

We recently posted a news item about improvements to a custom software application that we developed for a client involved in the midstream service industry. They manage joints of pipe from cradle to the grave, and we recently released two new modules that has extended their tracking ability even further.

Milling: Getting in from the beginning

The first module allows the client to barcode joints of pipe as they are being milled. In addition, they capture the run number, coil number, and other data that helps identify that specific piece of pipe. After all of this has been completed, they commit the joint to the system.

The first module allows the client to barcode joints of pipe as they are being milled. In addition, they capture the run number, coil number, and other data that helps identify that specific piece of pipe. After all of this has been completed, they commit the joint to the system.

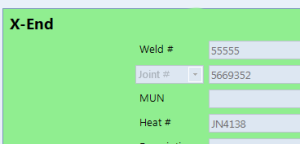

Welding: the second step in the process

The second module follows the joint of pipe to welding. This part of the process is very important for quality control, as welds are a common point of failure in a pipeline. One employee stands on the X-End of the pipes to be welded, while another stands on the O-End. Both of their computers are connected to the same session in the system, and updates made on one end are reflected on the other.

Each worker scans the pipe to verify that the joint number is correct, and then the double jointed (DJ) weld is completed.

Afterwards, the pipe is x-ray tested from the X-End to ensure that the weld is sound. Coming additions to the module will allow the client to track this test and then follow the pipe on to coating.

Afterwards, the pipe is x-ray tested from the X-End to ensure that the weld is sound. Coming additions to the module will allow the client to track this test and then follow the pipe on to coating.

Each incremental step in the process of adding to the application allows our client to provide customers with a more and more complete view of what is happening to their property.

For more on solving business problems with custom software, check out this post. Or read about how codifying your business logic in custom software can help set your company apart…

Entrance Enhances SpreadBoss Towards Cradle-to-Grave Pipe Tracking

Last year, we announced the completion of SpreadBoss, a custom software logistics support tool that allows thousands of joints of pipe to be tracked, providing customized inventory reports and creating a pipeline status history database. Entrance and TG Mercer have pushed the ability to track joints of pipe from cradle to grave that much further with the recent release of new modules for milling and welding.

Previously, TG Mercer would take custody of joints of pipe, assuming that they had been correctly milled and coated. They can now can insert their own employees at the very beginning of the process, allowing joints of pipe and their whereabouts to be entered into the system that much earlier. After this point, TG Mercer employees follow the pipe to the welder, where further quality control can be performed on-site.

This improved tracking ability has helped TG Mercer make more strides towards preventing inventory loss, in addition to giving customers better visibility into where project hold-ups are coming from at the very beginning.

For more on how this custom software solution works, check out our blog post, with screenshots.

To find out about the engineering intelligence behind the partnership with TG Mercer, read this article…